On the morning of August 16, 2024, Dr. Gao Gao Frost of the Light Metal Research Center of the University of Auckland, one of the world's five major light metal research centers, and Dr.Nick, technical director of New Zealand EnPot Company (Aneng plus), visited SIO . The special chief scientist of SIO, Professor Tie Jun of North China University of Technology and Dr. Xiao Hao, general manager of Beijing SIO led the team members to receive, and opened a deep exchange and discussion on the current measurement technology and application prospects of aluminum electrolyzer.

Annenga company introduction

Founded in 2017, Annenga is the commercialization of the results developed by the University of Auckland, New Zealand, one of the world's five largest light metal research centers. The company's technology can increase the energy utilization rate of electrolytic aluminum plants by about 30%, and can help electrolytic aluminum plants make more full use of renewable electricity.

EnPot

Deepen cooperation and exchanges between the two sides and promote the technological revolution of aluminum industry

During the meeting, Lei Jun, manager of the technology department of SIO Technology Co., Ltd, first introduced the company's development history, product series, application results, technological innovation and future planning, and the company's team showed a very strong interest in our products and technological innovation, and its high enthusiasm made the exchange atmosphere heated up rapidly.

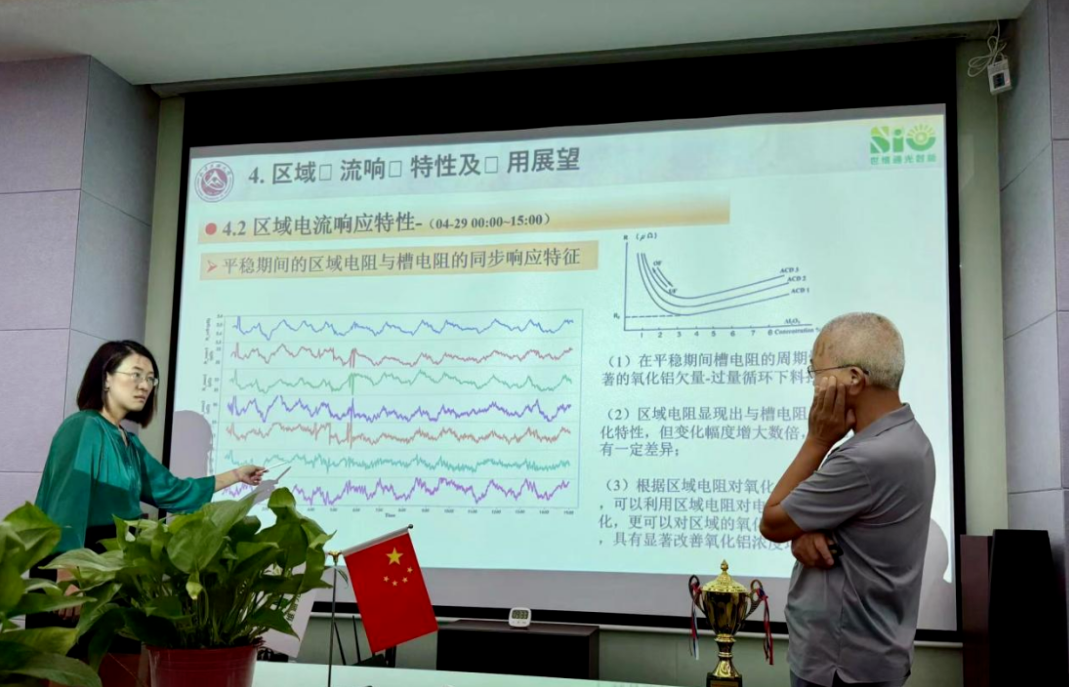

Then, in the "Accurate Measurement and Application Outlook of Regional Current of Aluminum electrolyzer" shared by Professor Tie Jun, he pointed out that online measurement of current distribution of electrolyzer is the data basis of intelligent electrolyzer control system, and introduced the latest research results made by SIO in the technical solution of regional current measurement, measurement data analysis results, and blanking control strategy. Attract Annenga company team warm discussion.

Two sides meeting exchange site

At the end of the meeting, Annerga company introduced its research results and market applications, shared their experience and professional insights, and brought new perspectives and ideas to the exchange.

The visit of the Anenga company not only further enhanced the understanding and trust between the two sides, but also laid a solid foundation for the future cooperation in the accurate measurement of current in the aluminum electrolyzer area. Dr. Gao spoke highly of the breakthrough significance of the anode region current optical fiber online measurement system for aluminum electrolytic cell health monitoring, process improvement and efficiency improvement, saying that it has realized the idea of optical fiber accurate measurement of electrolytic cell proposed by Prof. Mark Taylor, PhD supervisor 12 years ago, and will bring a new technological revolution to the global electrolytic aluminum industry.

This exchange is not only a technical collision, but also an opportunity for cooperation. The two sides will take this visit as a starting point to further strengthen communication and cooperation, jointly promote the development of aluminum electrolytic cell current measurement technology, and contribute to the progress of the industry. It is believed that with the joint efforts of both sides, a chapter of cooperation full of innovation and breakthroughs will be opened.